Abundant in the earth’s crust and backed by a robust recycling infrastructure, aluminum is the lightweight workhorse metal for architecture and interiors. Its primary application is in construction, for smaller structural elements, and as complex molded parts for electrical systems. Highly conductive yet light enough to be used in aircraft, it is ubiquitous in all industries.

However, not all aluminums are equal. For most applications, the metal is alloyed with silicon, magnesium, or copper because pure aluminum is useless for anything structural. The different types are named as numerical series—the mostly pure aluminums make up the 1000 series (aluminum foil is 1235), with alloyed versions found in the 2000s all the way up to the 8000s. Construction mostly uses the 6000 series, with some 5000s used for their strength and easy workability.

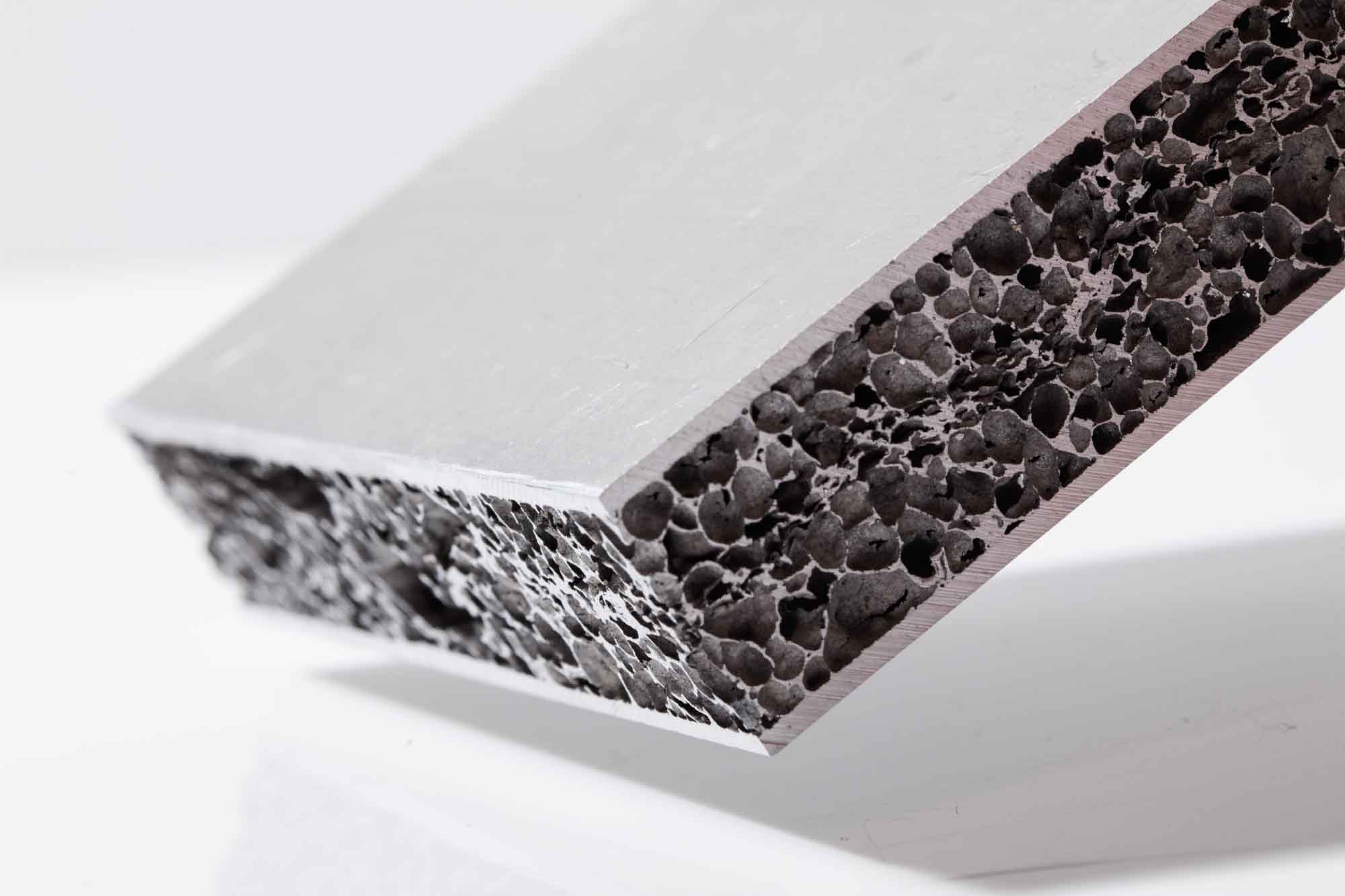

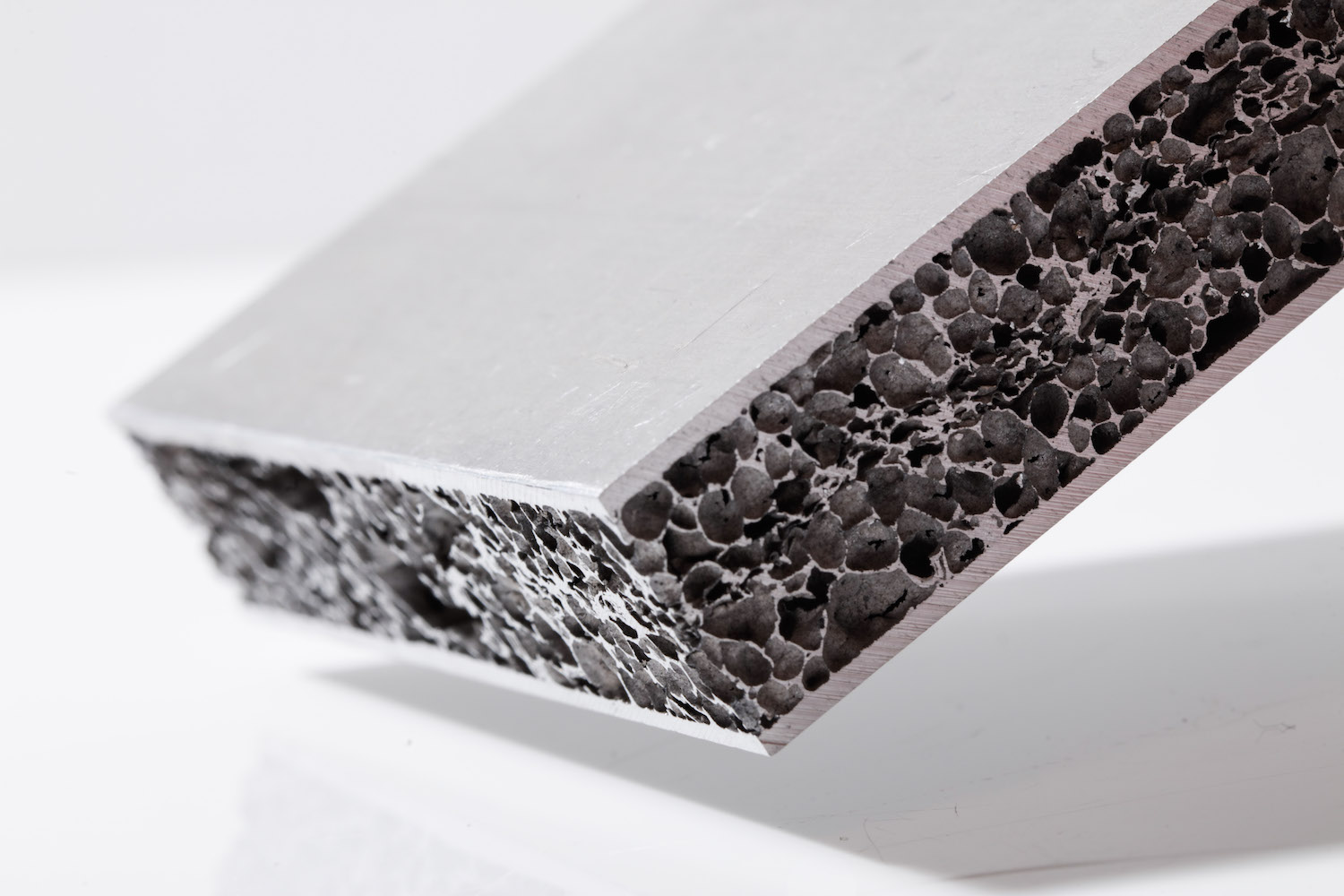

MC 912101 / Aluminium-Foam-Sandwich (AFS®)

Somewhat surprisingly, aluminum is a highly reactive metal. It would dissolve completely in air or water if it were not for the thin oxide coating that immediately forms on the metal’s surface when it is produced. This layer, essentially like sapphire in structure (but without the impurities that make the gemstones blue), is transparent, hard, and resistant to most chemicals. The process of artificially building this layer is called anodizing. While harder and more sustainable anodizing has recently resulted in better-protected metal parts, innovations in alloying are making aluminum almost as strong as stainless steel.

Recycling

Blessed with the ability to be infinitely recycled, typical aluminum is sold with around 60 percent post-consumer recycled content. The construction industry uses 85 percent recycled aluminum that incorporates factory offcuts and scrap. Apple has added 100 percent recycled aluminum products to its line, but those rely on waste from the same factory as the main constituent. The challenge in getting to higher percentages of post-consumer recycled content is that it’s difficult to identify exactly what series the scrap is from. A higher- or lower-series alloy could change the properties of the aluminum part. In general, recycled aluminum takes only about 5 percent of the energy that the virgin metal requires for production.

Carbon Footprint

Efforts to lower the environmental impact of virgin aluminum production have centered on the use of renewable energy. For example, Century Aluminum’s Natur-Al products are made with energy from 100 percent renewable sources at its plant in Iceland. Meanwhile, Alcoa has carbon-free plants and uses a lot of hydroelectricity, cutting its reliance on nonrenewable energy for smelting to only 27 percent. Unfortunately, China almost exclusively still uses coal for this energy-intensive production process. Nonetheless, aluminum’s potential for recyclability makes it a true high-performance material, and an important component of a circular economy.

Explore more innovative materials in Sustainable Furniture and Building Materials.

“This article was written by the Material ConneXion Research team, a subsidiary of Material Bank. With over 25 years of experience Material ConneXion specializes in helping the world’s leading brands find innovative & sustainable material solutions – helping their clients reach new levels of performance while ensuring they are making the most environmentally responsible material choices. To learn more about how MCX can help your product development & packaging journey click here”